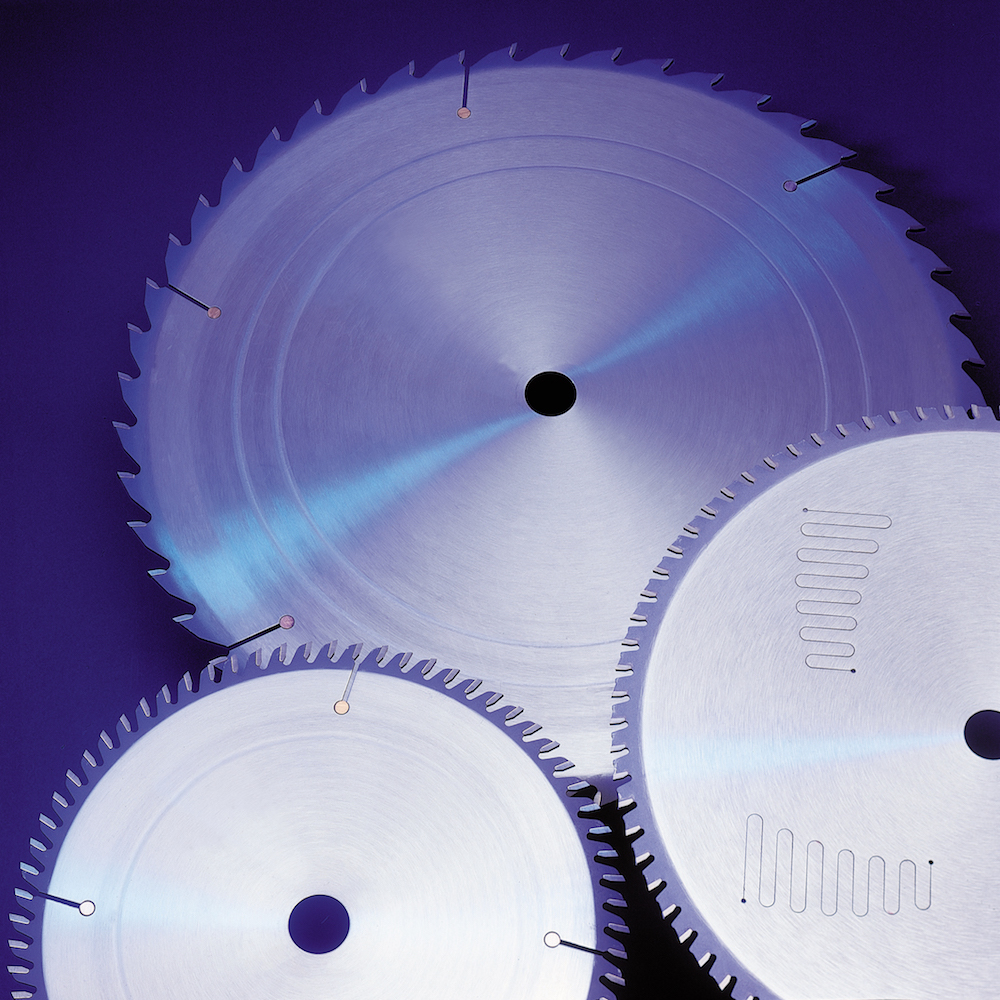

TUNGSTEN CARBIDE TIPPED (TCT)

Expertise:

We are one of the leading UK manufacturers of Industrial quality TCT circular saw blades. We can supply up to 1820mm saw blades. We offer free expert technical advice to our customers to assist in choosing the right blade for their needs.

Blade Manufacture

Tips are brazed with high temperature silver braze and free flowing flux to ensure all contact faces are wetted offering maximum adhesion. Fine diamond grit grinding wheels are used for a exceptionally smooth finish which results in less chip resistance and faster cutting.

Blade Design

The body materials have been selected to provide toughness and resilience and to support the carbide under heavy load. All blades are levelled and tensioned to give optimum performance at running speeds.

The tooth geometry is designed to suit the application with positive or negative rake angles, triple chip and chip breakers. We have a range of standard tooth geometry’s or can produce a custom design to suit customer requirements.

Sheffield Industrial Saws Ltd Service:

Manufacture and supply of segmental and solid bodied TCT saw blades and supply of spare tips.

Comprehensive re-sharpening and repair service

Technical advice on feed, speed, blade specification, repair, etc.

Recommendations on our Sheffmist Spray System and coolants.

Application:

High speed conventional cutting of ferrous and non-ferrous metals, wood, laminates and plastics.

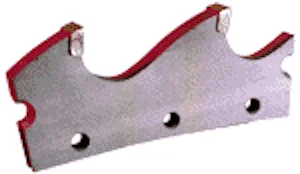

Segmental Carbide Saw Blade:

250mm to 1820mm (10 to 72 inches)

Segmental blades tipped with carbide to withstand the wear conditions associated with high speed cutting of abrasive non-ferrous alloys.

Body:

Chrome-Vanadium Steel

Tips:

P25 – P45 (S6) for Steel

Type K10 & K20 for non-ferrous materials

Sheffcarb Saw Blade:

360mm to 1820mm (14 to 72 inches)

Solid bodied carbide tipped blade designed for arduous steel cutting applications

Body:

Chrome-Vanadium Steel

Tips:

P25 – P45 (S6) for Steel

Type K10 & K20 for non-ferrous materials

OTHER TCT PAGES:

OUR BUSINESS

A key element of our business is the production of high quality Industrial Tungsten Carbide Tipped Circular Saw Blades (up to 1820mm diameter) for use in wood, metal, aluminium and plastic industries.

Our Tungsten Carbide tipped blades are produced to the highest specification using the best material available and offer a competitively priced, robust, long-lasting option for those who want more than just a throw-away, temporary solution to their cutting needs.

We have the flexibility to meet individual requirements for pinholes, expansion slots, copper plugs and noise reduction blades and can supply blades for all circular sawing machines. We also manufacture many other associated products including circular knives, alloy circular saws, and blanks for the diamond industry.

With our technical expertise and in-house design capabilities, we are able to create products to customers’ own specifications for all aspects of wood cutting and the food, building and turf care industries, as well as many other industrial cutting applications. Our methods combine state-of-the art modern production techniques and traditional technical skills to achieve the consistent high quality of our excellent blades.

We can liaise on the development of new products and offer facilities for customer own-branding if required. We also offer a full range of saw accessories and a TCT saw blade-reconditioning service to our customers.