CIRCULAR SAWS

Foremost in the SIS range of blades is the Hotsaw Blade used throughout the World in steel section rolling mills, the name Hotsaw being derived from the cutting application where red hot steel section is cut to rough length at the final stage of the rolling process.

Cutting steel at temperatures well in excess of 500° C is probably the most arduous application for any blade. Using manufacturing techniques developed over many years SIS produce what is widely recognised as the industry standard blade, produced and manufactured for SIS in England with flame hardened teeth, these blades are precision machined and subject to the attention of the Worlds leading Sawsmiths, apprentice trained craftsmen who through a combination of skill and experience ensure that SIS blades run accurate and true in the cutting application.

Our Segmental saw blades are recognised in the UK as the superior blade for cold metal cutting. The UK leading steel stockholders and fabricators specify the SIS 54” segmental saw as their preferred blade for heavy cutting. Sheffield has always been the UK centre for saw manufacture, we are proud that our company name now incorporates that of the “Steel City” reflecting the quality and care that goes into production and service of these blades.

Tungsten carbide tipped circular saws of 800mms to 1500mms diameter are a speciality for SIS, used in the most demanding applications for metal cutting, we can offer new blades at highly competitive prices and service/repair to the highest accuracy with blades delivered/collected by our in-house fleet of vehicles.

Used for friction cutting cold carbon and alloy steels, usually multiple pieces. Finer tooth pitches used to generate frictional heat during cutting. High pressure cooling and clearing of teeth and generous body cooling is vital to blade operation.

Used for cutting red hot carbon and alloy steels (over 750°C). Larger tooth pitch, possibly with extra gullet clearance, to prevent filling in. High pressure cooling and clearing of teeth and generous body cooling is vital to blade operation.

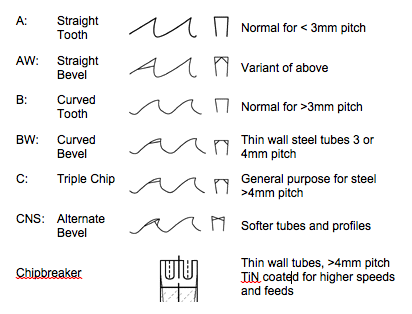

High speed conventional cutting of ferrous and non-ferrous metals, wood, laminates and plastics. We are one of the leading UK manufacturers of Industrial quality TCT circular saw blades and offer free expert technical advice.

High speed conventional cutting of ferrous and non-ferrous metals, wood, laminates and plastics. Standard material is M2 Super High Speed Steel - can be manufactured from M35 Cobalt Steel for cutting high alloy steels.

Conventional cutting of ferrous and non-ferrous metals. Segments are manufactured from HSS with three hardness zones to provide a tough joint zone and a hard working zone with a tempered transition zone between the two.

For use in agricultural machines, mainly for ripping and occasional crosscutting. Made of chrome vanadium. We are one of the few saw blade manufacturers who can manufacture large circular saw blades.

Our information will help you purchase the correct saw blade for your machine and the materials that you are cutting. However, if you need further advice, we are only a phone call away and happy to help.